The Sanitary Weld Butterfly Valves are built for use in a wide range of applications and working pressures.

Sanitary Weld Butterfly Valve is designed for use in a broad spectrum of applications and working pressures. These FDA-compliant valves provide reliable performance and smooth operation. The stem diameter provides particularly low flow resistance, ensuring gentle product treatment for low and medium-viscosity products. They are used in food & beverage processing, pharmaceutical and chemical products, industrial fluid applications.

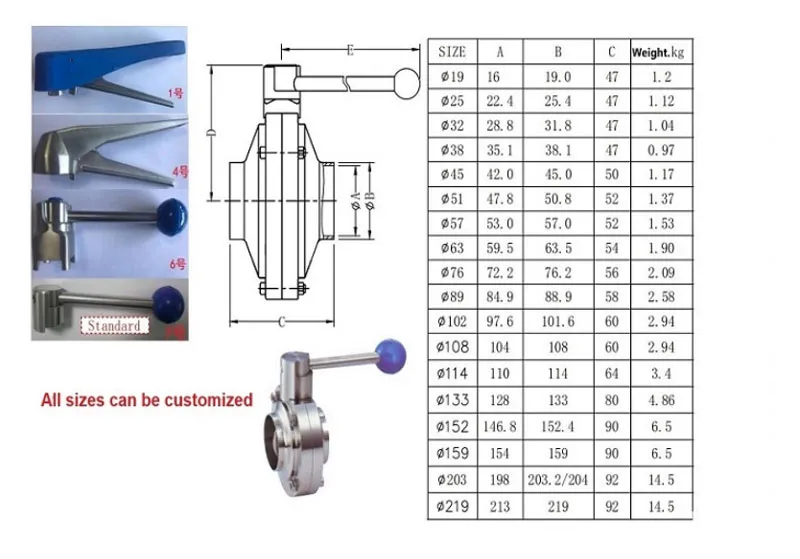

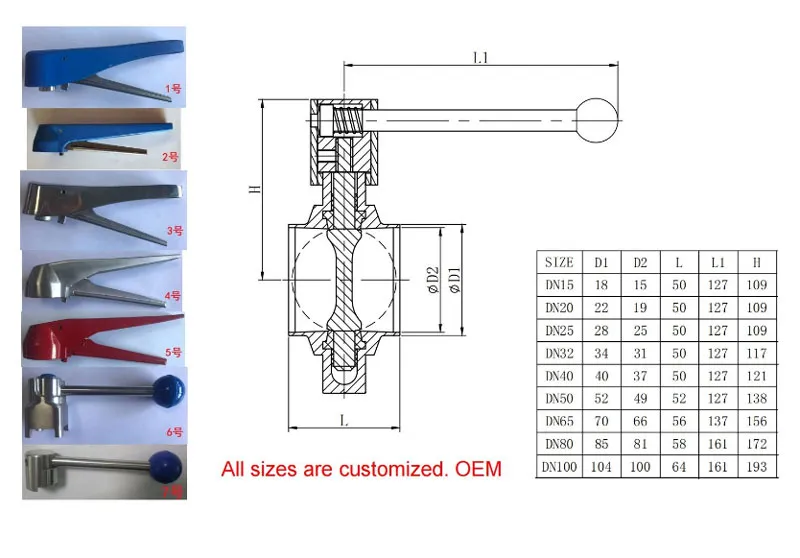

| Size | DN10-DN300, 1/2″-12″ |

| Body&Disc Material | AISI 304 or 316L, (EN1.4301/EN1.4404). |

| Temperature | -20℃ to +220 ℃ (It depends on the seal) |

| Max Pressure | 145psi (10bar) |

| Seal | EPDM, Silicone, FKM, TEFLON, PTFE, NBR |

| Pipe Joint Systems | DIN SMS RJT 3A ISO IDF |

| Manual Operation | Pull handle, Multi-position Plastic handle, Multi-position Stainless Steel Handle |

| Pneumatic Operation | Compatible with Single-acting or Double-acting Pneumatic actuator |

| Surface Treatment | Ra16-32µin (0.4-0.8µm), Ra 32µin (0.8µm) as default. |

| Connection Type | Clamp End, Thread End, Weld End |