Stainless Steel 3-piece Ball Valve Full Bore with PTFE seat design, no dead angle. Manufactured from premium grade Stainless 304 or 316L, ensuring that it remains incredibly strong as well as to prevent rust.

The 3-piece ball valve is WOG rating,1000psi designed to used in water, oil, gas, food & beverage processing, pharmaceutical and daily chemical, industrial fluid applications. Connection End with tri-clover/clamp, weld or thread.

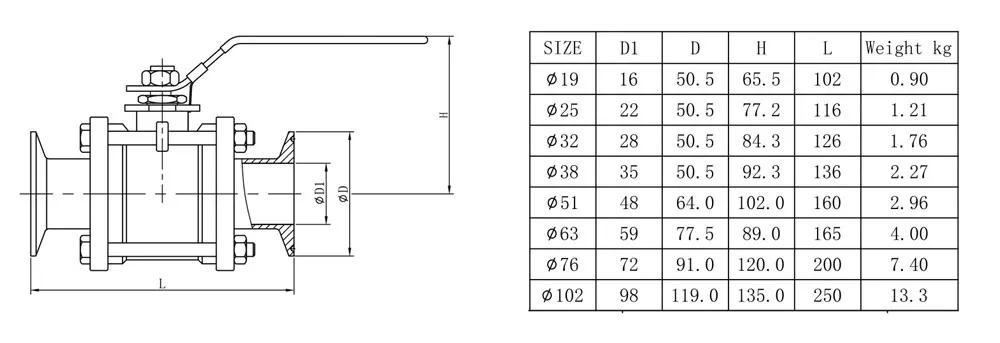

| Size | DN10-DN100, 1/2″-4″ |

| Body & Disc Material | AISI 304 or 316L, (EN1.4301/EN1.4404). |

| Max Temperature | 220 ℃ (450F) |

| Max Pressure | 145psi (10bar) |

| Seal | PTFE |

| Pipe Joint Systems | BSP, NPT, BSPP Thread, clamp |

| Manual Operation | Manual, pneumatic, electric all interchange |

| Surface Treatment | Ra16-32µin (0.4-0.8µm), Ra 32µin (0.8µm) as default. |

| Connection Type | Clamp End, Thread End, Weld End |

Why use a 3 piece ball valve?

For processes that put heavy demands on valves, having a 3 piece valve is more convenient than one or two-piece ball valves. When seats and seals need to be routinely replaced, having three pieces allows for easy disassembly, servicing and reassembly without having to do major cutting on the pipe.

Three-piece ball valves also allow for elastomers to be changed to accommodate different process conditions, temperatures, pressures and flows.