Sanitary check valves also named as "non-return valve" are designed for use in process piping systems to prevent backflow of fluids. They are manufactured using AISI 304 or 316L stainless steel. These products are 3A certified and suitable for all sanitary conditions, including those in the food, beverage, and pharmaceutical industries.

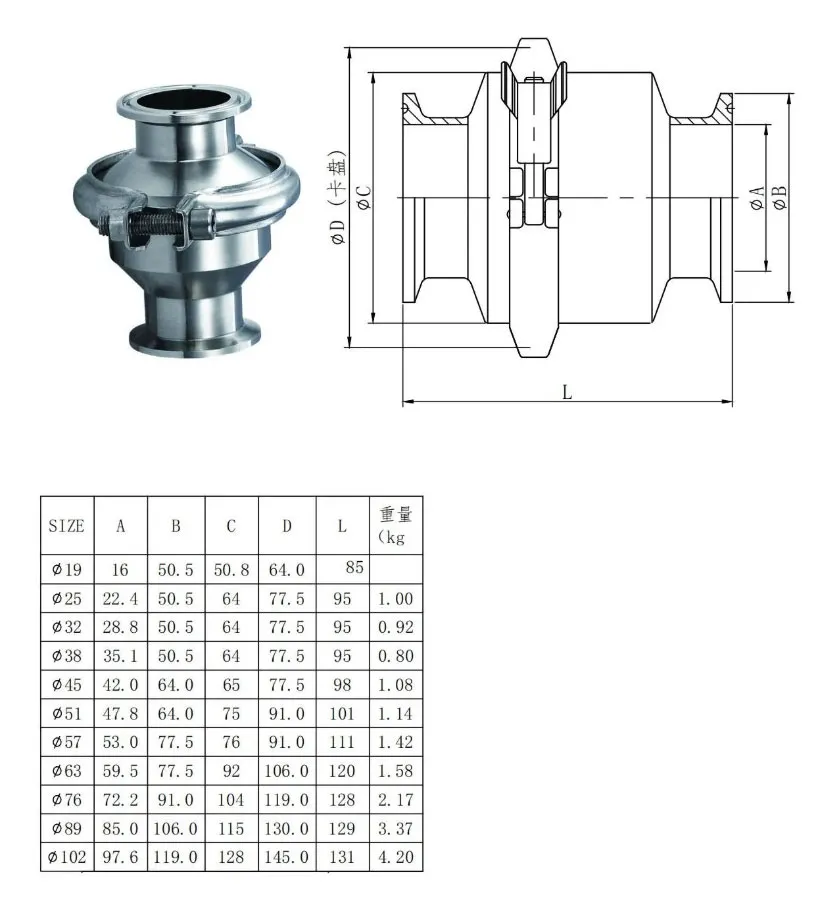

| Size | DN15-DN100, 1/2″-4″ |

| Body&Disc Material | AISI 304 or 316L, (EN1.4301/EN1.4404). |

| Temperature | 14 ~ 248°F (-10 ~ 140°C) , Silicone EPDM |

| Max. pressure | 145 psi (10 bar) |

| Opening pressure | 1.5-4.5 psi (0.1-0.3 bar) |

| Seal | EPDM, Silicone, FKM, TEFLON, PTFE, NBR |

| Pipe Joint Systems | DIN SMS RJT 3A ISO IDF |

| Surface treatment | Ra16-32µin (0.4-0.8µm), Ra 32µin (0.8µm) as default. |

| Connection type | Clamp End, Thread End, Weld End |

The stainless steel valve body ensures nonporous, smooth surfaces and dimensionally stable construction. The valve body is in two parts, assembled by means of a standard clamp and sealed with a standard gasket. The self draining design of the lower valve body enables flushing of the product. Ribbed construction of the stainless steel disc resists heavy pressure hammer, minimize the resistance to flow and also serves as a guide to the valve plug.