Sanitary Racking Arm Valve, made of Stainless Steel 304 and 316L, is a critical component in the brewing and wine industry, enabling precise control of liquid transfer between different containers. The valve features a rotating siphon arm to guide liquid flow during the siphoning process.

| Material | Stainless Steel 304, 316L |

| Connection type | Clamp/thread |

| Connection Size | 1.5″-2.0″ |

| Max Pressure | 10bar (145PSI) |

| Working temperature | Max 180°C (Silicone), Max 150°C (EPDM) |

| Surface treatment | Ra16-32µin (0.4-0.8µm), Ra 32µin (0.8µm) as default. |

Racking Arm Valve is valve attached to a racking arm, typically used in the brewing, winemaking, and beverage industries. It facilitates the transfer of liquids from a tank, fermenter, or barrel while minimizing sediment pickup.

The racking arm is adjustable, allowing the user to draw liquid from different levels within the tank, avoiding sediment at the bottom.

Material:

Made from stainless steel (usually SS304 or SS316) for durability, corrosion resistance, and hygiene.

Valve Type:

Often includes a butterfly valve, ball valve, or sanitary tri-clamp valve for precise control during liquid transfer.

Connections:

Commonly available with tri-clamp fittings or threaded connections for easy integration into sanitary systems.

Seal Materials:

Equipped with food-grade seals like PTFE, EPDM, or silicone to ensure a tight seal and hygienic operation.

Applications:

Brewing: Transferring beer from fermenters or bright tanks while avoiding yeast or trub. Winemaking: Racking wine to separate it from lees (sediment). Beverages: Moving clear liquids in tanks with minimal waste.

How It Works:

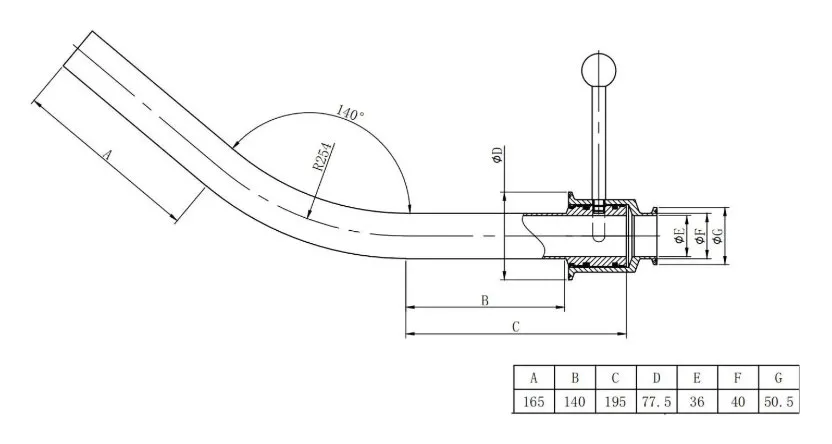

The racking arm is mounted at the side of the tank and can be rotated to adjust the angle.

By rotating the arm, the valve draws liquid from the desired level, ensuring clarity and reducing contamination with solids at the bottom.